Processed Cheese Production

Processed Cheese is a blend of cheese, water and other permitted additional ingredients (depending on legislation) such as milk powder, cream, anhydrous milk fat, vegetable fat, whey proteins, caseinates, starches and coloring.

The viscosity, texture, p.H. balance and binding of the water and fat content is achieved by the use of a variety of emulsifying salts. These include phosphates and citrates. Both spreadable and block type processed cheeses have similar ingredients but the proportions of these and manufacturing procedure vary according to the end product.

The Process

Formulations and actual processing methods vary, however a typical process can be summarized as follows:

- The cheese is washed and scraped then chopped or ground into smaller pieces.

- The pieces are melted in a scraped surface cooker which blends the cheese with water, emulsifying agents, milk proteins and other added ingredients. These are sometimes prepared as a separate premix. Typically cheese spreads have 20 - 40% added water. Block/Slice varieties contain less, typically 2 - 25% added water.

- Cooking at between 160 - 195ºF or higher follows. The cooking time for cheese spread type products is between 10 - 15 minutes, for block types 4 - 5 minutes is more common.

- Temperature is raised for pasteurization, typically around 265 - 300ºF.

- The product is transferred to packing. With spread products this would normally be combined with passing through an inline mixer/homogenizer.

- Finally the product is cooled. Spread products are cooled rapidly. Block/sliced products are allowed to cool more slowly; this enables the desired texture and consistency to be obtained.

The Problem

The mixing stage is a critical part of the manufacturing process. Correctly dispersing and activating the emulsifying agents, milk proteins and salts is the key to a stable end product with a good texture or mouthfeel. The mixture of cheese and blended aqueous phase must then be intimately mixed to ensure correct reaction between the cheese protein, the milk protein and the salts. When using conventional mixing equipment a number of problems can be encountered:

- When added to water, emulsifying and stabilizing agents tend to form agglomerates which cannot readily be broken down by agitation.

- Long processing times are often required to complete hydration.

- Similarly, a degree of high shear may be required to obtain functionality.

- Poor hydration may lead to unsatisfactory “mouthfeel” and an unstable product leading to storage problems once the product has been opened.

- Protein agglomerates can lead to texture and fat stability problems. Stability of low fat products is difficult to achieve without focused shear and correct hydration of emulsifying agents and proteins.

The Solution

A Silverson High Shear mixer can overcome these difficulties, improving the preparation of the premix, or as a final homogenization stage prior to packing.

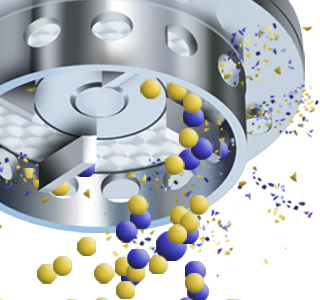

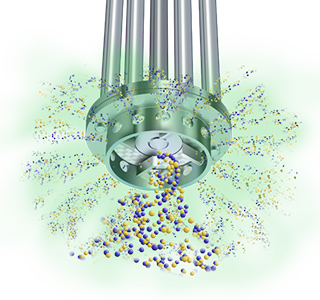

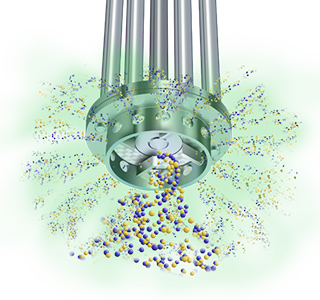

The advantages stem from the 3 stage positive mixing action of the high shear Silverson workhead. This operates as follows:

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and solid/powdered ingredients into the workhead. These can be added without the need for pre-mixing.

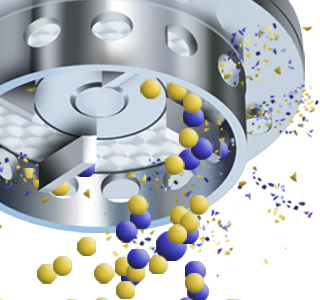

Stage 2

The materials are subjected to intense shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blades and stator wall.

Stage 3

The product is forced out of the stator as fresh material is drawn into the workhead. A circulatory mixing cycle develops in which all the material passes through the Silverson workhead, rapidly forming a homogeneous mix.

-

Stage 1

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws the liquid and solid/powdered ingredients into the workhead. These can be added without the need for pre-mixing.

-

Stage 2

Stage 2

The materials are subjected to intense shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blades and stator wall.

-

Stage 3

Stage 3

The product is forced out of the stator as fresh material is drawn into the workhead. A circulatory mixing cycle develops in which all the material passes through the Silverson workhead, rapidly forming a homogeneous mix.

The Advantages

- Premixes can be prepared in a fraction of the time taken by conventional methods.

- Agglomerate-free mix, giving improved texture and stability.

- Improved yield and batch-to-batch consistency.

The batch size, viscosity at mixing temperature, formulation and type of ingredients determines which machine from the Silverson range is most suitable:

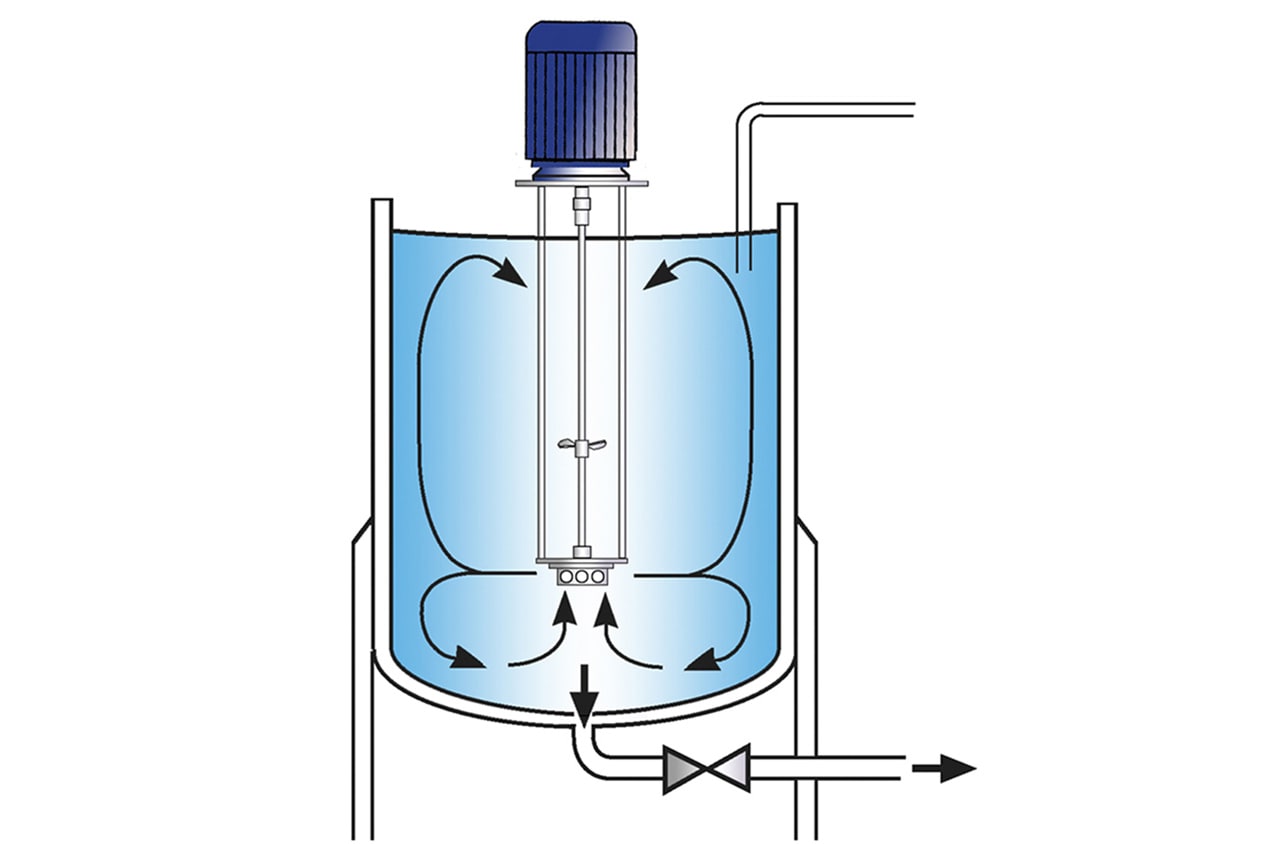

High Shear Batch Mixers

Premix

- Suitable for preparation of small to medium premix batches

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

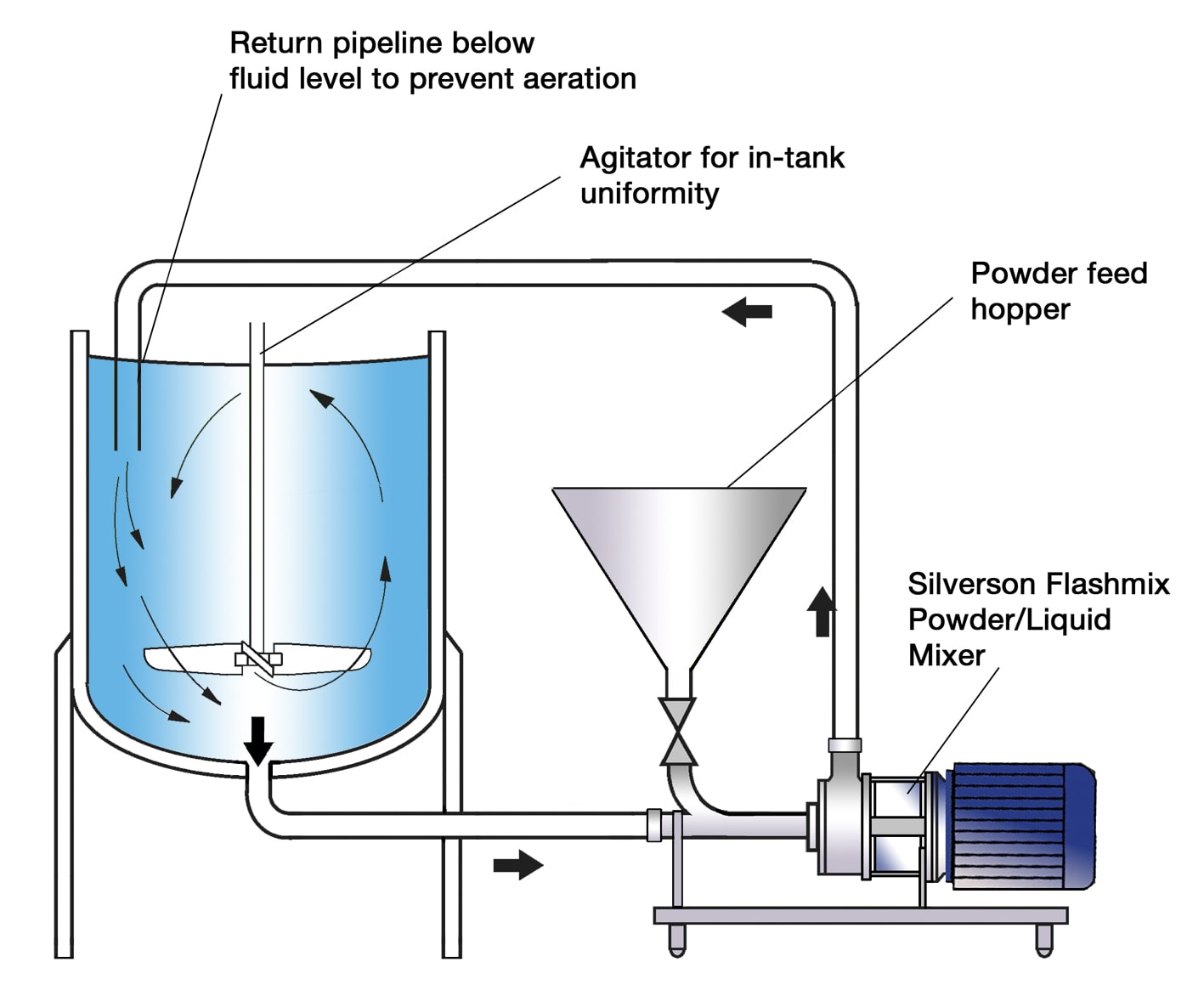

Silverson Flashblend

Premix

- Ideal for large scale premix preparation

- Capable of rapidly incorporating very large volumes of powders

- Minimized aeration

- Minimized cleaning requirements

- Controlled powder addition rate

- Minimum operator input required

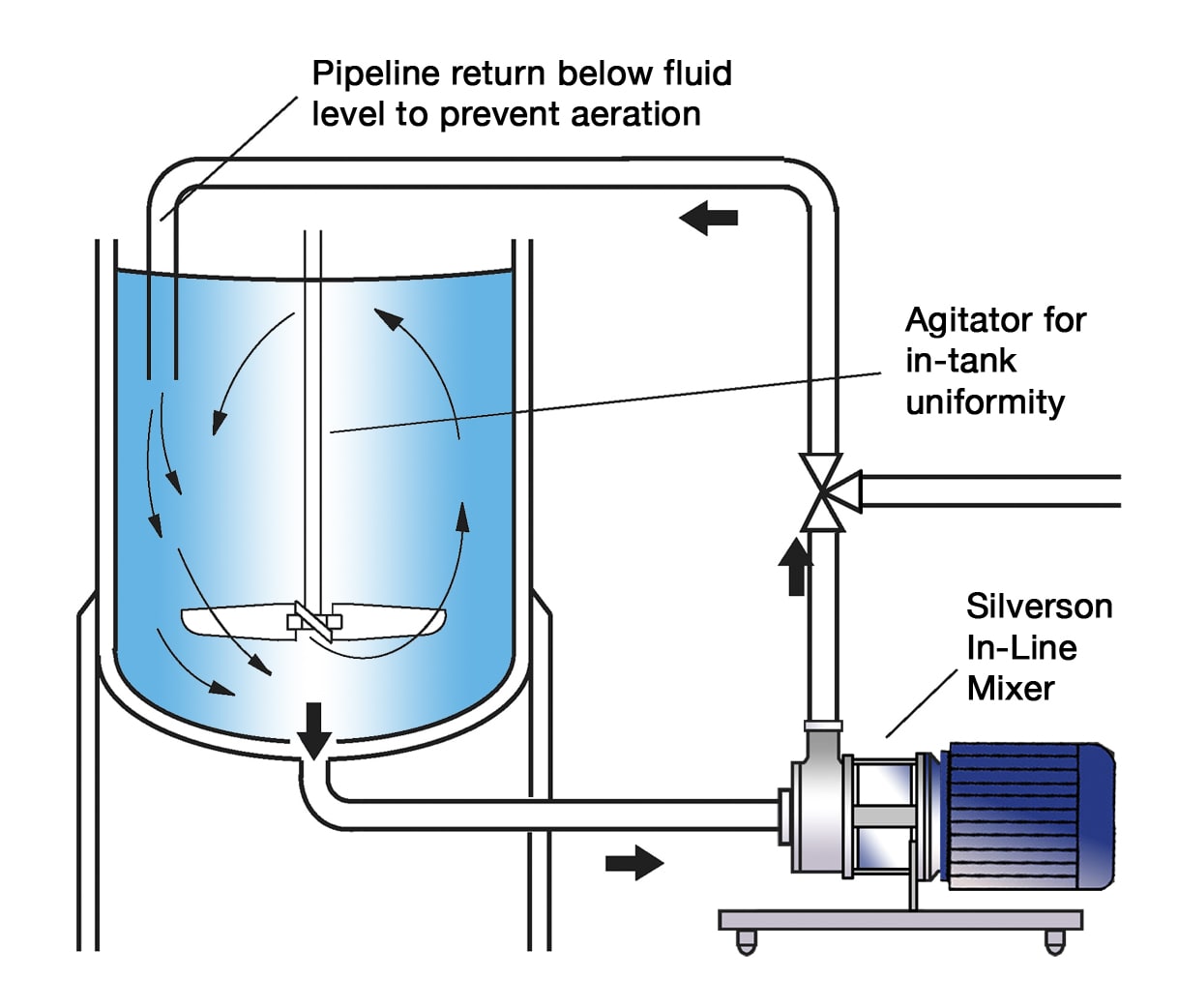

High Shear In-Line Mixers

Finished Product

- Used for single pass homogenization of finished product prior to packing

- Ideal for larger batches

- Easily retrofitted to existing plant

- Aeration free

- High Viscosity models available

- Ultra Sanitary models available